14th

October 2020

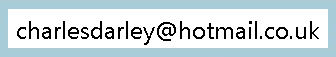

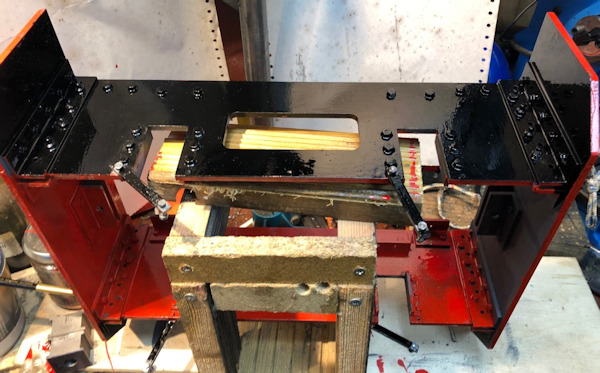

Today's job drilling cutting and fitting the Axle Box

keepers in place.

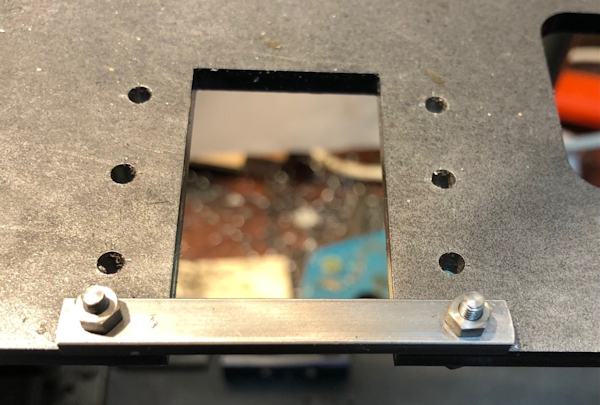

The photo shows just one of the four units fitted to-day

using 6BA nuts and bolts.

|

|

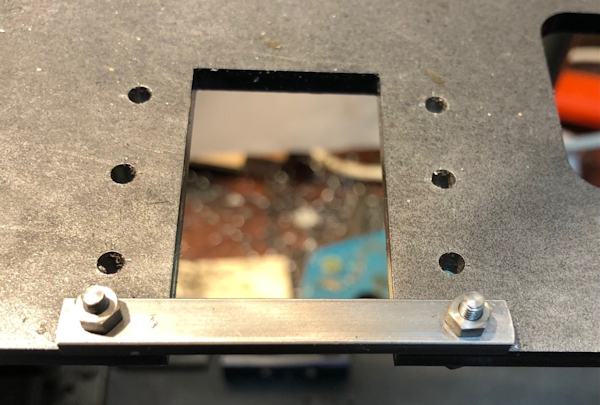

I am glad this

is all completed as the drills blunted and three broke

but they had done a lot of work so not complaining.

The photo shows the horn guide fitted.

All the cut bolt now need to be tidied up.

I may also decide to fit the extra piece for the

coupling rod fixing rather than using a nut and

bolt. I will have a think about that !!!

|

|

15th

October 2020

The additional coupling fitted was made up and fitted.

|

|

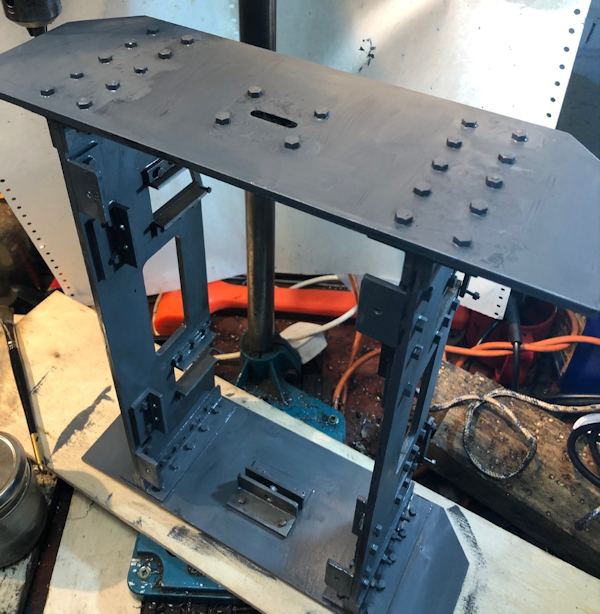

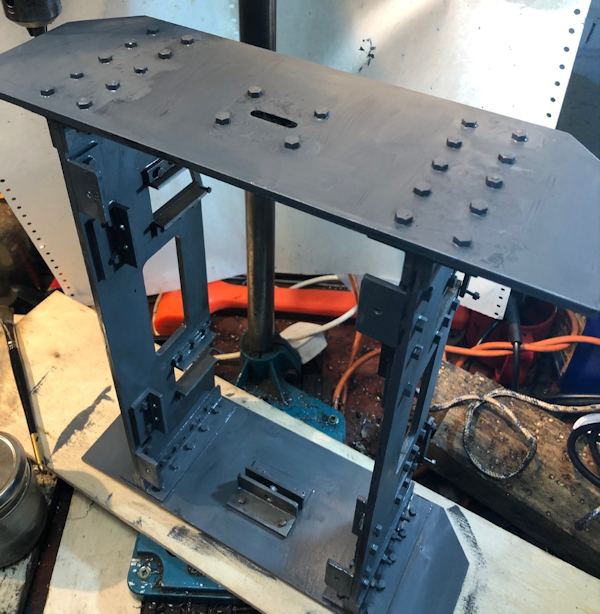

This is how

the chassis is at 12:30 today.

|

|

and now the

bolt ends have been cleaned up.

|

|

After a quick

flush off with degreaser and a blow dry it was into the

Sand Blasting cabinet and a quick sand blast.

The photo shows the primer coat of paint applied which

will be left over night at least before more paint is

applied.

|

|

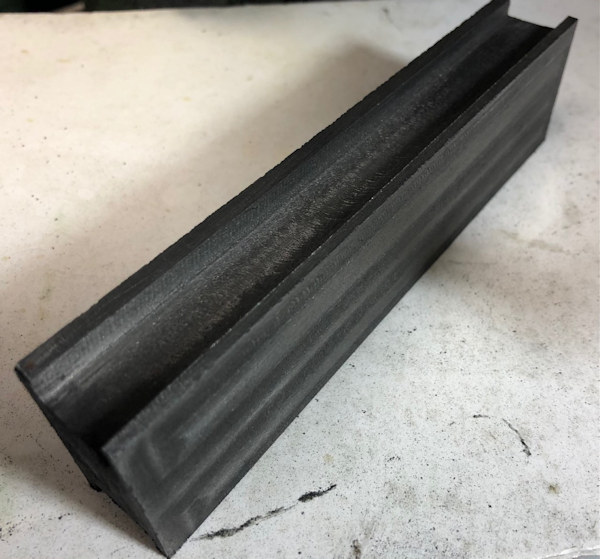

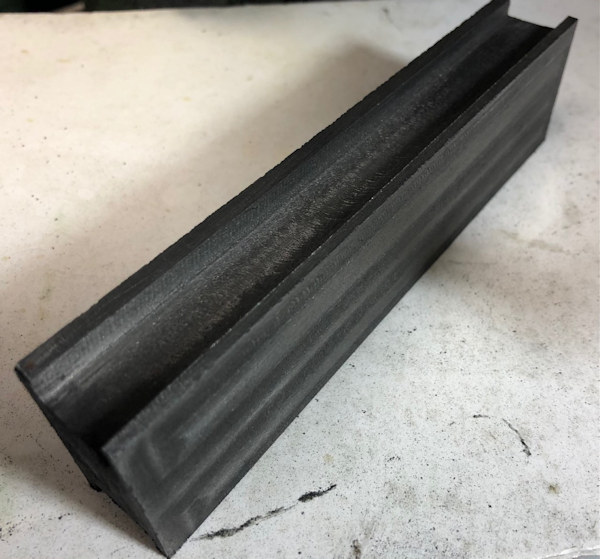

The Axle Boxes

come as a stick of 4 made of cast iron.

The metal was set up in the vice and a first cut taken.

Then more cuts including turning the billet over so that

all 4 side were at right angles to each other. This

takes a long time as I was only taking a 0.5mm cut.

|

|

This is not a

job to rust and it needs to be constantly measured.

Still after about 2 hours it is nearly ready to slice up

and bore for the axle.

|

|

16th October

2020

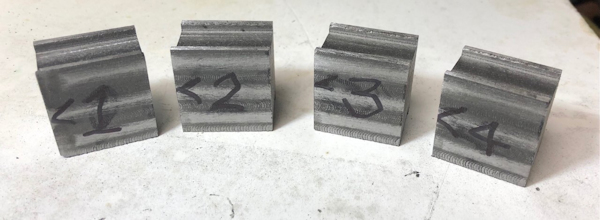

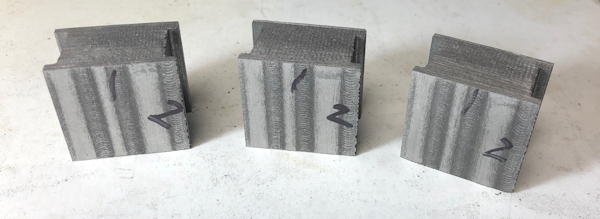

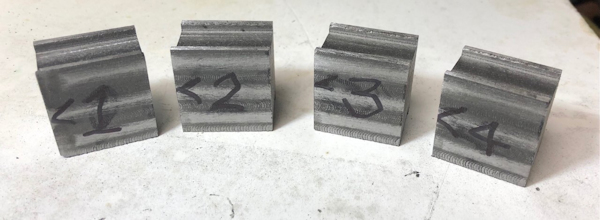

The first cut into the block of 4 axle blocks

|

|

All cut up and

numbered and an indication of the top

|

|

First one

marked and centre punched

|

|

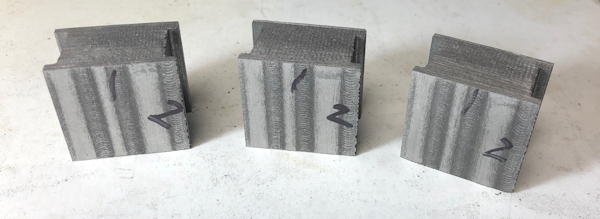

The others

marked so that when put in the 4 jaw chuck the 1 and 2

are aligned with the right jaws

|

|

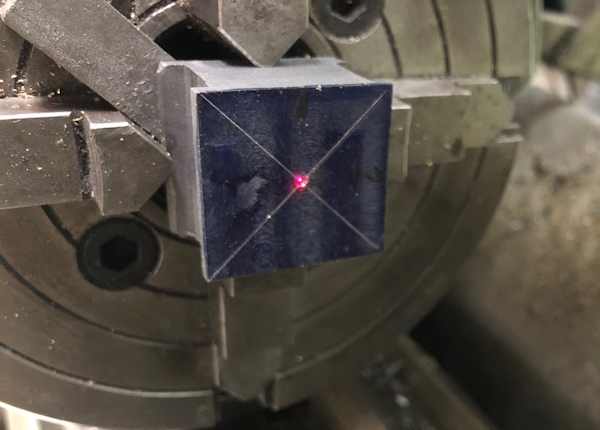

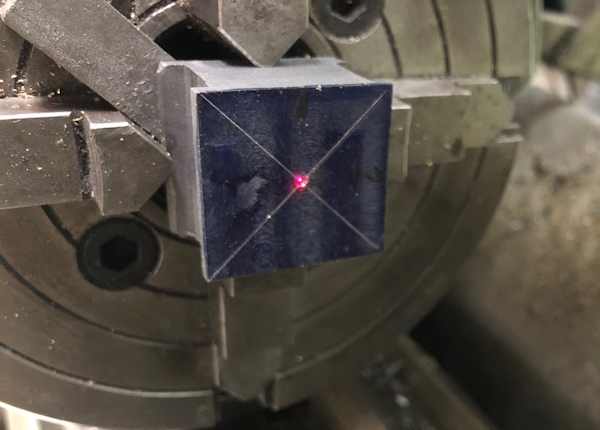

Set up in the

4 jaw chuck with Laser dot to locate centre

|

|

After using a

centre bore tool the drill was put through gently

followed by the 1/2" reamer

|

|

All four unit

fully machined

|

|

| and the last

operation was to check the fit and they all fitted !!!!

|

|

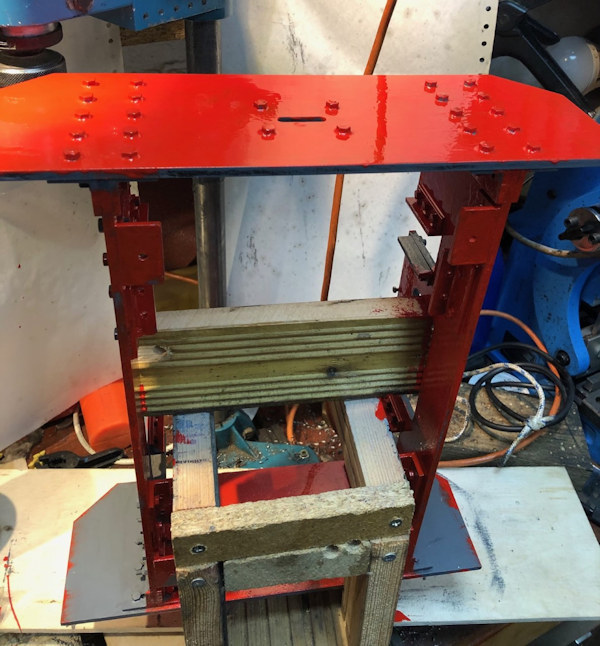

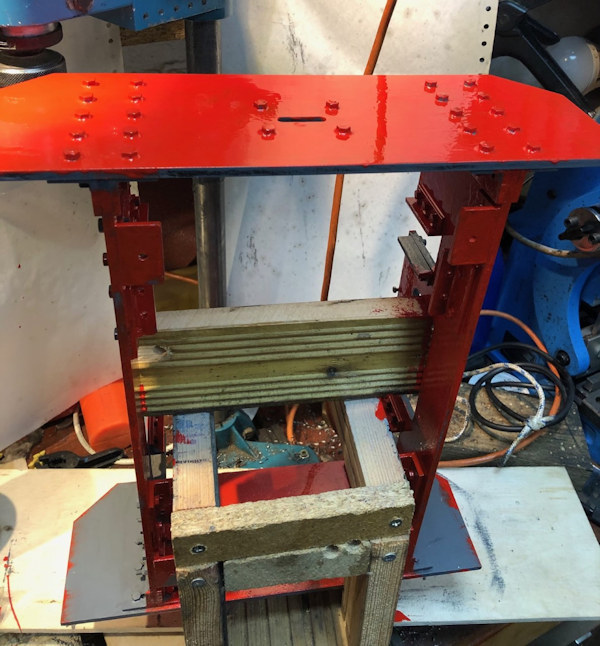

Pressing on

with a less make or break effort this afternoon a first

coat of red paint.

|

|

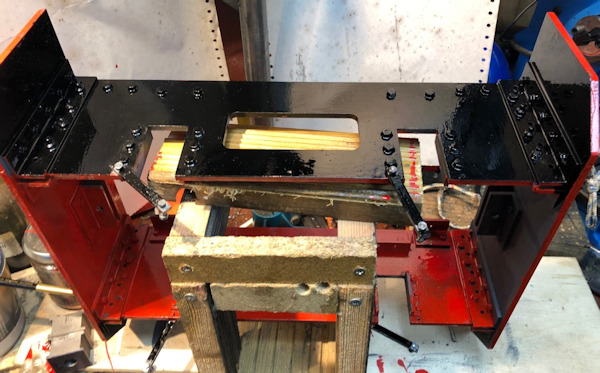

| and lastly the

first coat of Black |

|