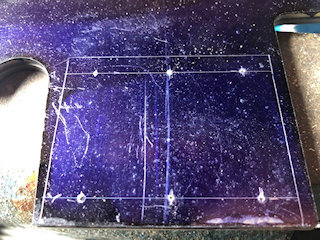

The frames steel was cut up and placed on a building board for a trial fit. Seeing that it fitted well on the 2ft x 1ft board I checked it on the electronic construction board and that too fitted well.

As I do not have a surface plate big enough I will be buying a piece of mirror glass and set that on the build board as a make shift surface plate.

I need to cut many more brackets from angle to make fixings for the frames in fact i need a total of 8.

I also watched this video

https://youtu.be/M2_TdwE2MRE

Deciding the placement of the holes in the angle piece I decided that with a width of 17mm inside the angle that from the edge I should have a gap of 4mm then space the distance to the inner hope should be 9mm leaving 4mm to the inner face.

Vertically with 20 to play with I would have the top holes 5mm down a gap of 10mm and that will then leave 5mm at the bottom ...

The picture show a sample angle piece set on a white box and this clearly shows where the inside edge starts. The drilled holes will be almost exactly on the diagonals !!

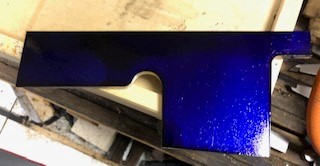

From the drawings I worked out that scaling 31/2" to 5" is an increase of 42% so the dimensions on the plan were so increased.

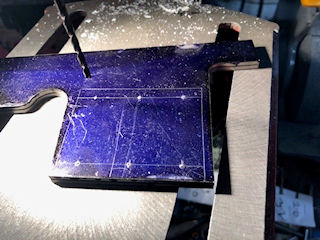

The photo shows the mounting piece covered in marking out blue.

The location of the punch positions was achieved by using an optical punch.