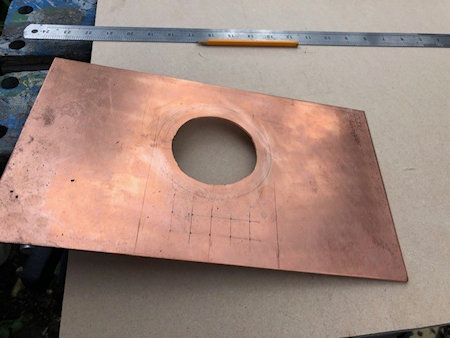

Throat plate

First mark our where I need to flange by chain drilling Then drill the holes for the stays and then cutting with a metal Chisel and finish by filing

Make up the former in MDF and drill holes to fix locating pins

With the throat place the work requires opening out the smaller hole to fit the former and continue this with period of annealing

A backing piece of MDF is also required to ensure the copper remains flat

Use a piece of MDF the size of the tube to check that the hole formed will fit the tube

Then former needs to be made to bend the sides of the throat

Remember to check square with a try square.

I have bought a piece of MDF 18mm thick which is quite heavy !! This is in preparation for cutting the formers for bending and folding the part for the boiler.

Tidying up the workshop ready to cut formers for boiler from MDF.

The size of the MDF that I need to cut takes account of two side and the front which is 4 1/4" plus 4 1/4" plus 4 1/4" so that makes 12 3/4" x 7 1/4".

The copper sheet is measured at 2.5mm so a circle must be drawn of 53.3mm Radius.

Today being the warmest in 2025 I decided to cut the hole in the former.

Cut the backing piece and cut the hole in it to match that of the front piece.